MINI CASE STUDY

THINKING OUTSIDE THE BOX

AMtec's Engineering team thinks "out of the box" to solve challenges

AMtec puts the old saying to work - - literally!

A new client engaged with AMtec to help them re-package their custom control panel from a standalone enclosure to an integrated chassis for their tool. As we completed the design and transitioned to manufacturing the prototype, the absence of the actual tool’s chassis where the control panel would be housed became the primary constraint. Our customer had a very aggressive delivery target, but it was impossible to build without the actual chassis, and no amount of expediting would solve this problem.

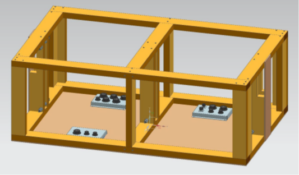

With a copy of the 3D model and the ingenuity of our Manufacturing team, we proposed to our customer “what if we simulated the chassis from wood?” Yes, wood!... not a material we’re accustomed to using in manufacturing custom control panels.

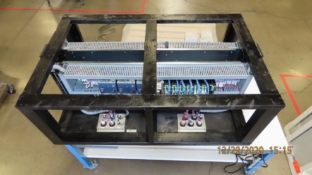

The idea was that the wooden chassis would allow us a temporary home for the 4 backpanels and a place to land the nearly 1000 wires. Once at the customer’s site, the controls could be extracted and transplanted to the metal chassis.

With our customer’s approval to substitute wood for the prototype, we proceeded.

The wood enclosure yielded some additional benefits: It allowed our Quality Assurance Team to conduct the crucial final step of electrically testing the completed product. And by fabricating the mock-up exactly to scale, we performed a valuable fit check of the chassis dimensions, thereby reassuring our customer that their design was mechanically sound.

Not only did we hit our customer’s aggressive delivery date, but this outside-the-box thinking helped us to strengthen a new relationship.

Project Inquiry

Got a project in mind? We'd love to talk about it with you. Please provide some info so we can get the conversation started. We'll be in touch!

"*" indicates required fields