MINI CASE STUDY

THE RISK-BUY PROCESS

AMtec uses the Risk-Buy Process strategically to accelerate lead times and reduce costs.

What is the Risk-Buy Process?

The Risk-Buy Process is a way of breaking the traditional, linear materials sourcing process that saves time in many cases.

Where product designs are still in development, the Risk-Buy process can help to significantly reduce cumulative lead times. It can also eliminate waste and reduce costs. For more than a decade AMtec has used the Risk-Buy process to help customers get their products or projects completed faster.

These days, when supply chain issues abound, using the Risk-Buy process can be even more beneficial, as it allows a customer to get a jump start on procurement, potentially avoiding a stalled product launch once final designs are completed.

Who Benefits from the Risk-Buy Process

The Risk-Buy Process can benefit multiple functions:

- Engineering: Often pressured to complete designs with aggressive timelines

- Supply Chain & Purchasing: Often pressured to expedite the quote and the final assembly

- Operations: Needs time to perform integration, validation, etc. of the assembly

- Product Group: Striving to be first-to-market with a new technology

- End Customer: Needs your product as soon as possible

How and When to Employ the Risk-Buy Process

If a project has time constraints or can benefit from accelerated delivery dates, the Risk-Buy Process can be used when the design is still in development, and a partial Bill of Material (BOM) has been created.

In a traditional Customer-Supplier relationship, the Customer has a partially completed design and a partial BOM (parts list). In many cases, the Customer’s design process may be at a strategic break point in the BOM development process.

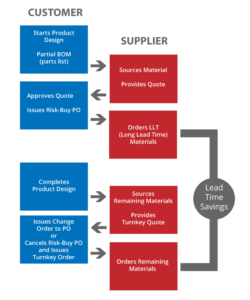

The Customer gives the Partial BOM to the Supplier, who begins sourcing the material, and ultimately provides a Quote to the Customer for the known components in the BOM (see graphic). Upon approval, the Customer issues a Risk-Buy Purchase Order to the Supplier, who then orders the Long Lead Time (LLT) material.

Once the full product design has been completed, the Completed BOM is made available, and the Supplier sources the remaining material and provides a Turnkey Quote. Upon approval, the Customer issues either a Change Order to update the Risk-Buy PO value to the Turnkey Price, or they cancel the Risk-Buy PO while issuing a Turnkey Order. The Supplier then secures the balance of the material not already ordered under the original Risk-Buy PO.*

*If the final design excludes some of the parts that were driven as part of the Risk-Buy PO, the Customer & Supplier will need to agree on how to disposition those items.

Results Using Risk-Buy Process: AMtec Industries

Using the process, AMtec Industries has consistently created lead time reductions for the completed product by an average of 4 to 10 weeks. The cumulative lead time reduction equals the time difference between the date that the Long Lead Time (LLT) material was ordered on the original Risk-Buy PO and the date that the balance of the raw material was ordered on the final PO.

In addition, a number of other key benefits are often created:

- Reduced time to market for new product

- Minimized wasteful (reactionary) expediting

- Reduced Cost by minimizing air freight, overtime, and/or expedite fees

- Allowed procurement and final design to occur in parallel

Talk to Us!

If you’d like to learn more about how AMtec Industries helps customers deliver faster and more reliably, including the use of the Risk-Buy Process, contact us today.

Project Inquiry

Got a project in mind? We'd love to talk about it with you. Please provide some info so we can get the conversation started. We'll be in touch!

"*" indicates required fields